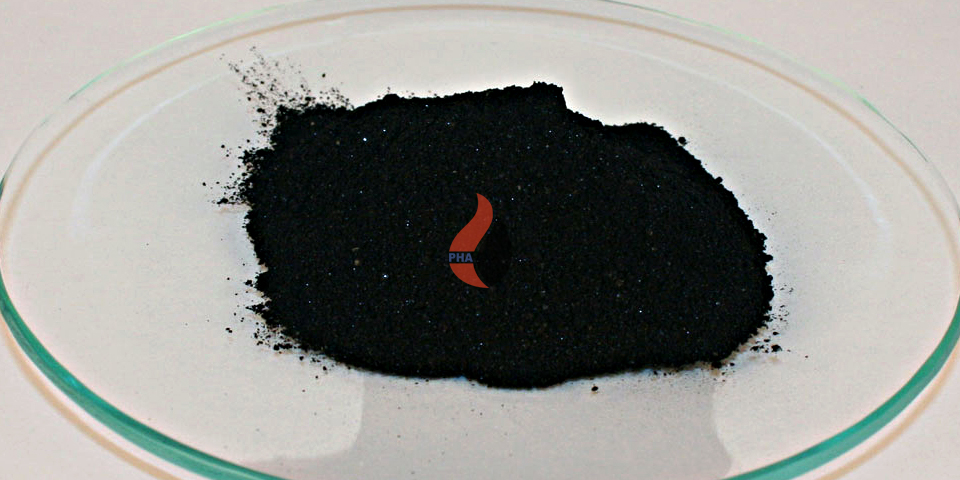

Powder Gilsonite

Gilsonite Powder / Powder Gilsonite / Micronized Gilsonite Powder / Asphalt Bitumen Powder / Natural Bitumen Powder

Pasargad Hakhamanesh Arshia.Co are a leading Iranian manufacturer of specialized in micronization process gilsonite powder or natural bitumen powder. we started manufacturing of Gilsonite, Natural Bitumen powder in 2003 at.

Today Pasargad Hakhamanesh Arshia.Co have wide experience in handling of Gilsonite/Natural Bitumen products and offer it's widest range in Iran Industrial use.

For industrial uses we have several grades suitable for all kinds of indsutries and applications. We offer coated as well as un-coated powders and Lump forms used in various applications for rubber, latex, drilling muds and other specialised products.

Our want show is in the field of mineral processing, and more particularly deals with a process for converting lump Gilsonite/Natural Bitumen into a micronized powder.

processes powder gilsonite

processes for the production of micronized Gilsonite/Natural Bitumen powder are dangerous and energy inefficient. Micronized Gilsonite/Natural Bitumen powder is quite often presently produced by pulverizing Gilsonite/Natural Bitumen lumps in mechanical milling equipment.

Particularly in circumstances where very finely sized particles are acquired, conventional milling results are dependent upon substantial energy consumption. As such, if it was possible to determine a method of production of micronized Gilsonite/Natural Bitumen powder which either used means other than mechanical milling or a mechanical milling process that significantly decreased the energy requirement, it would be desirable from an economic perspective. We can provides a micronized Gilsonite/Natural Bitumen powder product wherein 95% of the particles in the Gilsonite/Natural Bitumen powder product are less than about 75 microns in size.

In addition to the novel method of production of Gilsonite/Natural Bitumen powder disclosed herein, the micronized Gilsonite/Natural Bitumen powder which is the product of the process of the present invention represents an advance in the production of this product over the state of the art. The product which is produced using the method of the present invention, micronized Gilsonite Powder, will be comprised of particles of relatively consistent size and a very small micron measurement. Micronically sized Gilsonite/Natural Bitumen particles have significant commercial utility and benefits.

In addition, the micronized Powder Gilsonite, Natural Bitumen powder of the present invention will be of an increased quality or purity insofar as the impurities generated from milling equipment will not be present. In addition to the micronized Gilsonite/Natural Bitumen powder of the present invention, the intermediate micronized Gilsonite/Natural Bitumen powder cake is also a product which may have commercial utility and which is produced with significantly less energy and with excellent quality compared to products available in the prior art.

Prior art methods of production of Gilsonite/Natural Bitumen powder have typically concentrated on mechanical milling processes.

Mechanical milling of lump Gilsonite - Natural Bitumen, particularly where the desired effect is to mill that product to a powder of a small particle size has many limitations including the safety of the process itself as well as that mechanical milling of this nature consumes large quantities of energy and is hard on the milling equipment itself.

The micronized Gilsonite/Natural Bitumen powder recovered from the process of the present invention could either be packaged or stored for use in this form, or could be blended with additional ingredients.

Blending of the micronized Powder Gilsonite, Natural Bitumen powder in question with other ingredients dependent upon its end-use will again be a conventional technique or use conventional equipment as will be understood by one skilled in the art and on that basis the specifics of a blending step are contemplated within the scope hereof.

Finally after checked technical expert come in to packing system or tank of packing by 2 line a technical expert select according your order or line big bag and or line packing.

According report buyer we can do packing 25 kg by 2 layers laminate or big bag 1MT by size 95x95x120 for container 20 (Feet).