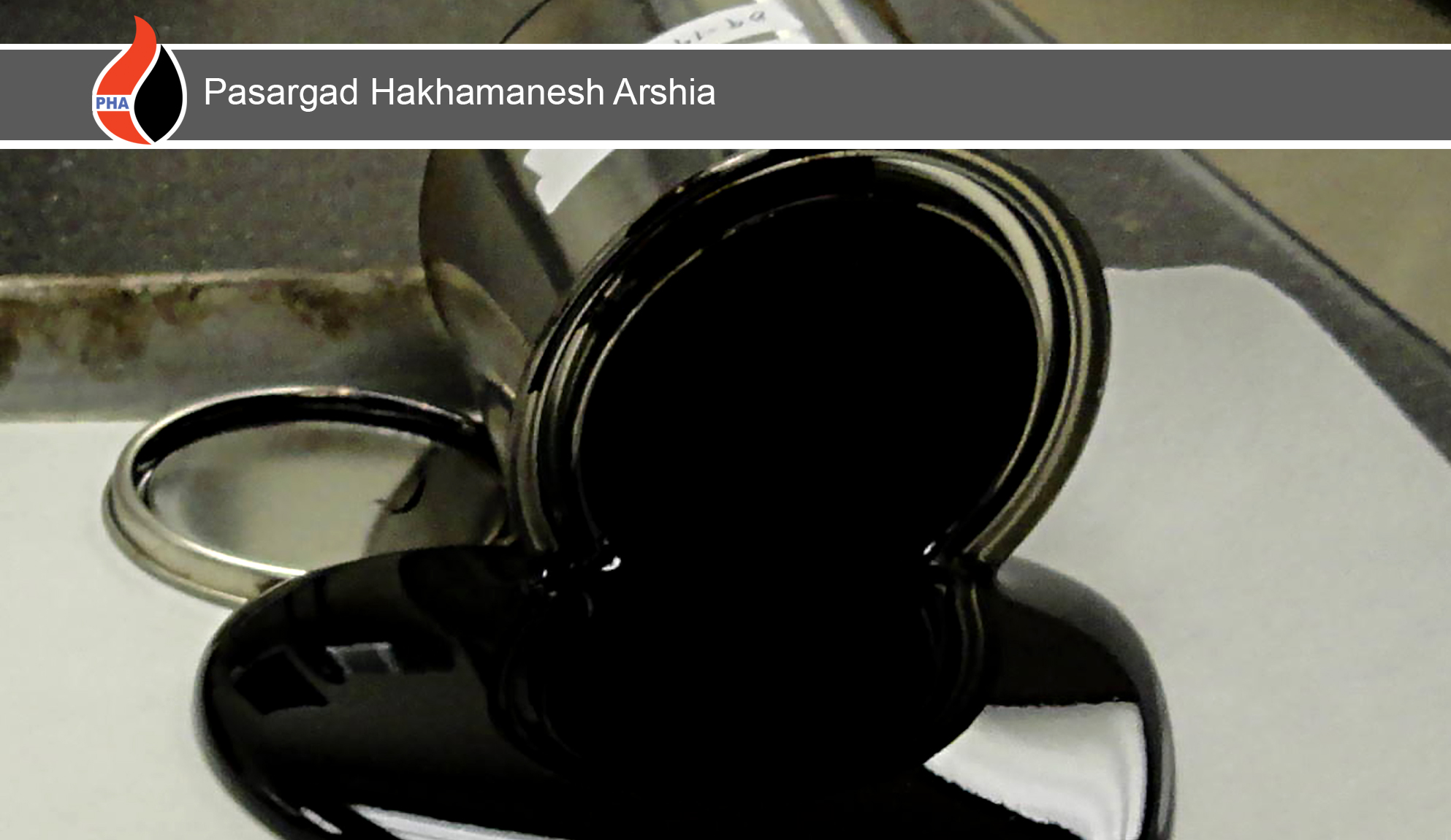

Petroleum bitumen

Petroleum bitumen

Bitumen that are obtained directly from the refinery vacuum in the distillation tower or are briefly exposed to the aeration process are called pure bitumen. These bitumen should be homogeneous and free of water and the heating temperature should never exceed 175 degrees Celsius.

Petroleum bitumen in the refinery is obtained from the distillation of crude oil. At the refinery, crude oil is first pressed in the furnace the environment is heated to a temperature of 300-350 C˚ before entering the tower. Inlet feed to the tower is partly liquid and partly they are steam.

The liquid part consists of higher boiling point components and the vapor part contains lower boiling point components which are the columns go up and are separated. Therefore, light components such as gasoline, kerosene and gas oil, at this stage are separated. Heavier components of crude oil, which is a complex mixture of high molecular weight hydrocarbons they leave the tower. This mixture needs to be separated before it can be fed to bitumen manufacturers they have instruments. Most of this mixture is bitumen and the rest is lubricating oils. For purification and to separate them the temperature must be increased to more than 400 C˚. Due to the high temperatures causes molecules to break down and cause thermal damage, the pressure inside the tower must be reduced, the temperature rises it is necessary to reduce the separation. Thus the rest of the atmospheric distillation tower from 350-400 C˚ in the hot furnace and then enters the vacuum distillation tower (tower vacuum) which has a pressure of 10 to mmHg 100 inside the column, from below, the superheat water vapor flows. As a result, water vapor flows separation of light volatiles from the top of the tower and its exit to other columns for separation. Non-material the escape, most of which is bitumen, comes out of the bottom of the column. It remains or remains vacuum tower is used as feed in making bitumen with different grades and the residual viscosity of the tower is different. Crude oil depends on the temperature and pressure of the vacuum tower during the process.

Also depending on the type of crude oil can be it designed the column to produce bitumen of different grades. Although bitumen obtained from the vacuum tower can be used directly, but sometimes bitumen the result does not have the appropriate physical properties and needs to be modified, the most important of which is the air is blowing in the bitumen.